GPSS Engineering partners with leading global companies focused on sustainable energy, constantly incorporating the latest technologies to improve the quality of our business.

PC280

It is now possible to generate electricity from unused energy sources such as factory waste heat and geothermal energy.

The PC280 is a binary generator that primarily operates using geothermal or waste heat as its energy source. It boasts a strong track record of successful installations worldwide and is one of the few binary generators that continues to operate stably over the long term. Additionally, with a rated output of 280kW, this product is eligible for regulatory exemptions under the Electric Utility Industry Law.

280kW Rated Output

The system is capable of generating up to 280 kW of electricity from hot water and steam at temperatures ranging from 90°C to 150°C.

Easy Maintenance

Shell and tube heat exchangers developed with geothermal heat in mind allow for easy and quick maintenance.

Short Delivery Time & Minimal Installation Cost

Since it is a mass-production model type generator, we have realized a short delivery time of 7~8 months. It contributes to a significant reduction in construction time.

TES70/120

Small-scale binary power generation system

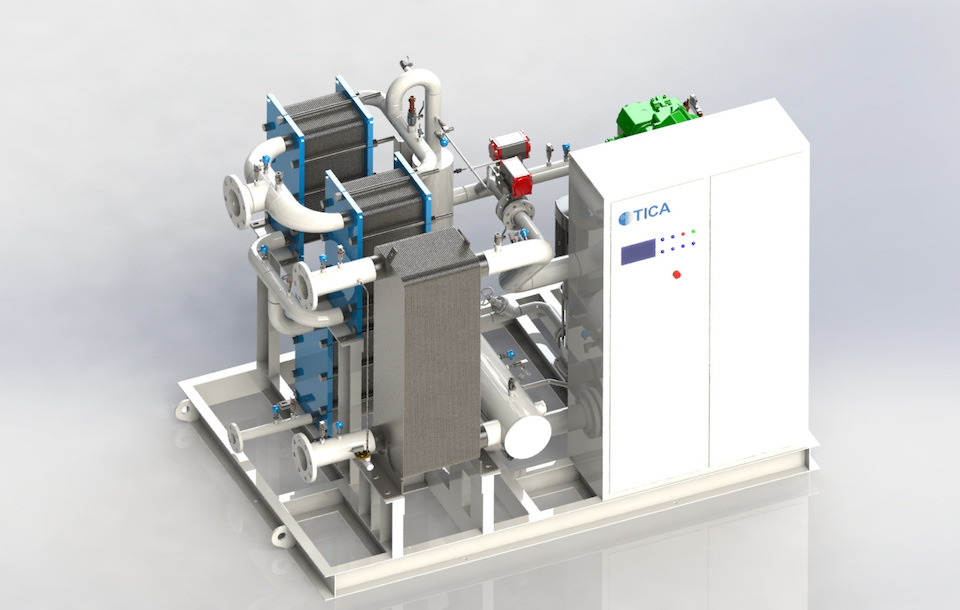

In order to meet the needs of customers around the world, TICA has officially released a binary generator (TES70/TES120) with a smaller output than PC280, and GPSS Engineering will begin handling this product in 2025.

The TES70/TES120 can generate power using low-temperature/small-volume heat sources, which have been difficult to utilize for power generation until now. We will make the best proposal according to the heat source conditions.

Compact design is realized by adopting plate heat exchangers for the evaporator and condenser. Installation in a small space is possible.

Compact design

The use of a plate heat exchanger makes it more compact than the PC280.

Installation in narrow spaces can also be considered.

Operation with new refrigerant is possible

The system can operate with a new refrigerant (HFO-R1233zd(E)) that can replace the refrigerant (HFC) used in conventional binary power generation systems.

Operating know-how cultivated with PC280

This product is manufactured by TICA, the same company that produces the PC280, which has a proven track record as a GPSS.

It employs a control mechanism and remote monitoring system based on the operational know-how cultivated with the PC280.

Binary

Generator

Binary generator with uniquely designed radial outflow turbine

EXERGY conducts research, development, design, and manufacturing of binary generators equipped with uniquely designed radial outflow turbines, based on advanced technology. Binary generation offers the advantage of easier maintenance compared to other solutions, as the turbine itself does not come into direct contact with the heat source. Additionally, EXERGY’s binary generators are known for their ability to provide optimal designs tailored to the specific heat source, offering solutions up to 50MW.

Rated Output of 1MW – 28MW

Its use depends on the temperature and application. 11 different working mediums of heat sources are used, with a temperature range of 90°C~350°C.

Innovative Technology

The world’s highest power generation efficiency of 30% for a binary generator has been achieved with our uniquely designed multi-stage high-efficiency radial outflow turbine.

Case Studies

The system has been installed in 54 facilities totaling 475 MW around the world.